Machine Division

Machine Division

NOW E&S Co, Ltd. specializes in manufacturing centrifugal separator and complex reinforced fiber rebar with the application of eco-friendly purification technology.

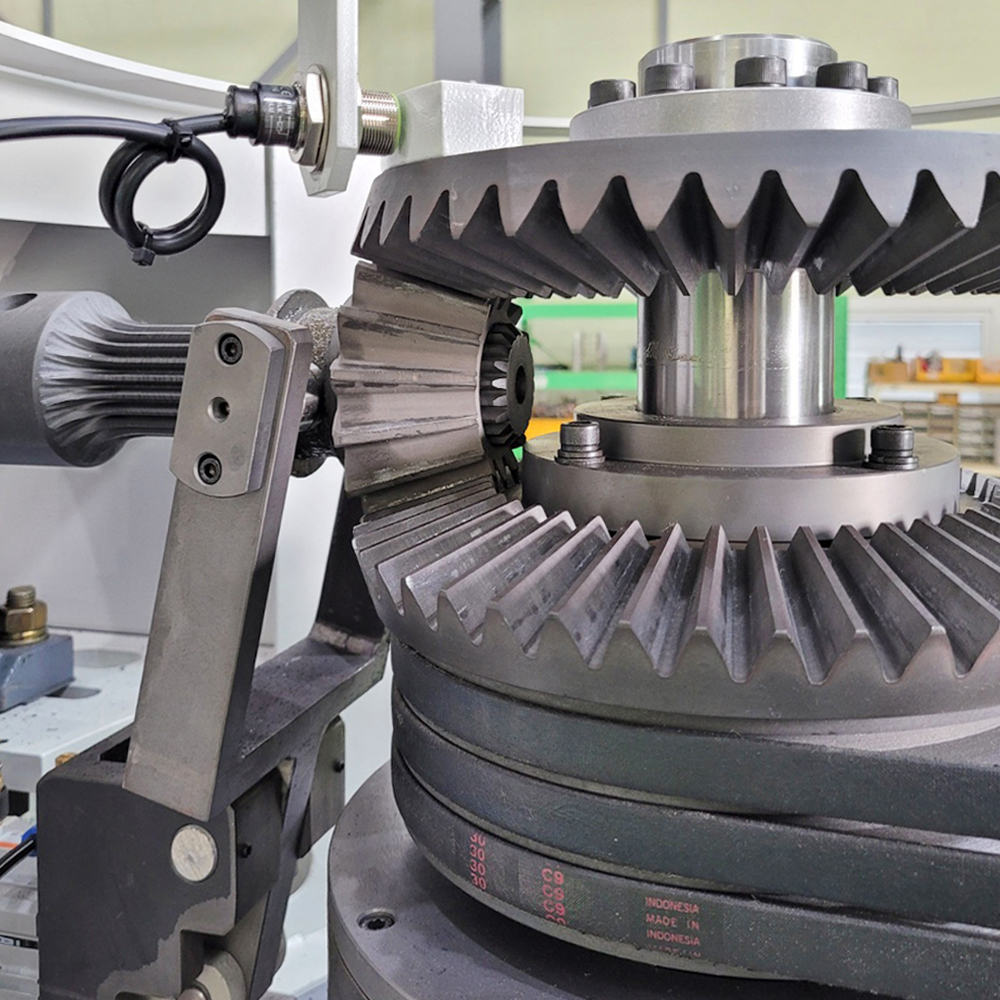

The centrifugal separator has a manual model with lower drainage structure (domestically patented), an automatic model based on high-speed and strong centrifugation mechanism, a solid-liquid model helping to improve the livestock environment, and a dual model supporting 24-hour continuous operation. For user convenience, the equipment drains down the cleaning liquid in its sludge bucket in order to reduce the bucket weight and easily attach and detach the tank. By shortening a sludge cleaning time, the next-generation centrifuge helps to improve customer productivity. Based on high speed and strong centrifugation mechanism, the equipment is applicable to highly-viscous oil separation. Like an expensive centrifuge, it is easily capable of treating fine types of sludge, including whetstone powder, carbon, glass dust, quartz, and ceramics.

The complex reinforced fiber rebar manufacturing machine is the equipment of producing carbon fiber rebar and glass fiber rebar. It was developed in the global trend according to which steel rebar is replaced by fiber reinforced complex materials in order to expand the lifespan of buildings and improve their quality. In addition, the developed equipment is suitable for construction structure safety & quality improvement work. As a leader in the future complex new materials area, NOW E&S Co., Ltd. strives to develop a technology.

[50875] 20-20, Techno valley 1-ro, Jillye-myeon, Gimhae-si, Gyeongsangnam-do, Republic of Korea TEL. +82-55-337-2947 FAX. +82-55-322-2947 E-MAIL. now@nowens.co.kr

[50875] 20-20, Techno valley 1-ro, Jillye-myeon, Gimhae-si, Gyeongsangnam-do, Republic of Korea TEL. +82-55-337-2947 FAX. +82-55-322-2947 E-MAIL. now@nowens.co.kr