Machine Division

Machine Division

- Overview

- Manual Model

- Automatic Model

- Solid-Liquid Model

- Dual Model

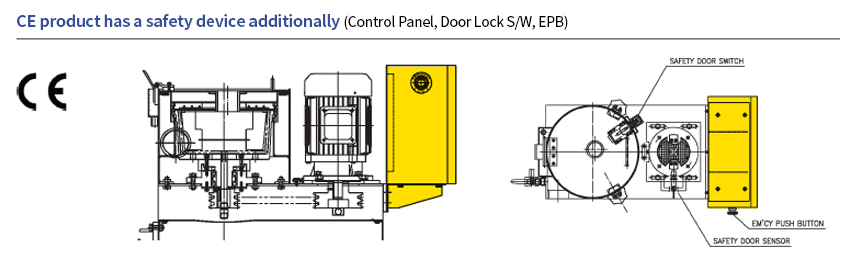

Centrifugal Separator (CE)

- The equipment has a manual model with lower drainage structure (domestically patented), an automatic model based on high-speed and strong centrifugation mechanism, a solid-liquid model helping to improve the livestock environment, and a dual model supporting 24-hour continuous operation.

- For user convenience, the equipment drains down the cleaning liquid in its sludge bucket in order to reduce the bucket weight and easily attach and detach the tank. By shortening a sludge cleaning time, the next-generation centrifuge helps to improve customer productivity.

- Based on high speed and strong centrifugation mechanism, the equipment is applicable to highly-viscous oil separation. Like an expensive centrifuge, it is easily capable of treating fine types of sludge, including whetstone powder, carbon, glass dust, quartz, and ceramics.

- Since lower drainage structure was applied to the manual model, the centrifugal separator is capable of circulating a variety of cleaning oil, including cutting oil and lubricating oil. Therefore, it can have the same effect as conventional automatic equipment in terms of reuse of process water.

- Manual Model

- Automatic Model

- Solid-Liquid Model

- Dual Model

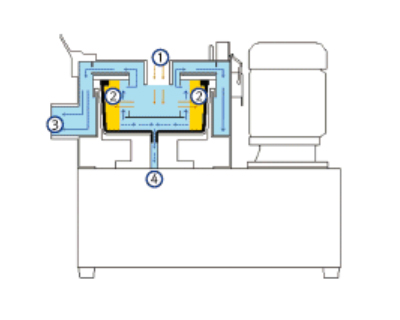

Operation principle of manual processing flow

Manual filtration process

- 01Supply of polluted solution (inlet)

- 02Sludge separation and deposition (inside wall of rubber bucket)

- 03Ejection of cleaning oil (ejection hole)

- 04Release of residual cleaning oil (outlet)

When the polluted solution supplied by a processing machine is fed to the centrifugal separator as a cleaning device through the inlet, the polluted solution is separated into cleaning oil and sludge by the centrifugal force of the rotor. The separated sludge is deposited in the inside wall of the rubber bucket. The separated cleaning oil is fed to the processing oil supplier through the outlet in a circulation type.

Manual sludge discharge process

- 01Rotor stops (rotor)

- 02Residual cleaning oil is discharged (outlet)

- 03The cover of the centrifugal separator is opened (cover)

- 04Sludge is automatically separated and cleaned (rubber bucket)

When the centrifugal separator stops to remove sludge, the rotor also stops and several liters of residual cleaning oil are discharged through the patented lower outlet. Once discharge is completed, it is possible to open the cover of the centrifugal separator, and separate and clean the rubber bucket as a sludge bucket.

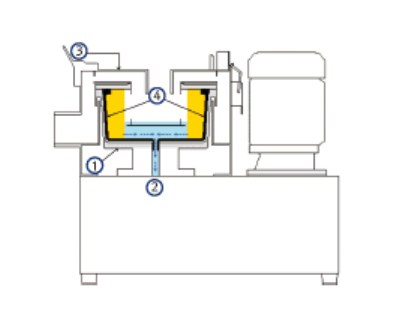

Operation principle of automatic processing flow

Automatic filtration process

- 01Supply of polluted solution (inlet)

- 02Sludge separation and deposition (rotor)

- 03Ejection of cleaning oil (ejection hole)

- 04Release of residual cleaning oil (outlet)

When the equipment starts to run after the centrifugation time and sludge cleaning time are set up through the operation panel, the polluted solution supplied by a processing machine is fed to the centrifugal separator through the inlet, and then is separated into cleaning oil and sludge by the centrifugal force of the rotor. The separated sludge is deposited in the inside of the rotor, and the separated sludge is fed again to the processing machine through the outlet. When the centrifugal separator stops, the residual cleaning oil is discharged through the lower outlet, and is fed again to the storage tank or processing machine.

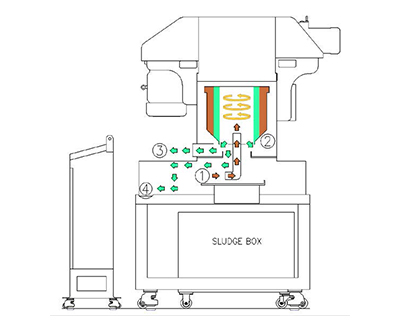

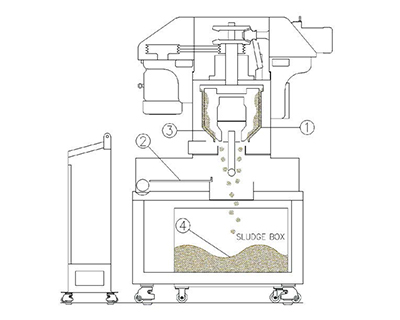

Automatic sludge discharge process

- 01Rotor stops (rotor)

- 02The cover of the centrifugal separator is opened (cover)

- 03Sludge is cleaned (scrapper)

- 04Sludge is stored (sludge box)

When the equipment reaches the centrifugation time set in the operation panel, it automatically switches to cleaning mode. At this time, the rotor stops. After the rotor stops and the cover on the bottom of the device is open automatically, the scrapper rotates clockwise/counterclockwise. The sludge deposited in the inside of the rotor is discharged and stored in the sludge box.

Main Features

- Centrifugation for maximized user convenience through lower drainage structure

- After centrifugation, the residual cleaning oil in the sludge bucket is drained. So, the weight of the sludge buckets can be reduced. It is easy to attach and detach the bucket.

- Minimum vortex-vibration through streamlined frame structure

- Vortex-vibration suspension through streamlines frame structure, minimization of the product size and installation area for an equal treatment capacity

- Maximized particulate filtration performance through high speed and strong centrifugation mechanism

- Easy filtration of particulate matters, such as whetstone powder, carbon, lens and mobile phone liquid crystal, glass, aluminum, and stainless silicone sludge

- Maximization of the lifespan expansion of grinding machine and the improvement in product

- Effective for reducing product defects and improving quality by expanding the replacement cycle of expensive diamond whetstone and minimizing the impurities-induced surface damage through particulate filtration improvement

- Unnecessary expensive consumables used by conventional filters

- Unnecessary replacement of expensive consumables used by magnetic separator, paper filter, filter press, and others; easy maintenance cost saving of users

- No separation of expensive chemical additives for special purpose; low solution consumption; excellent deterioration prevention

- Effective for lowering the temperature of water-soluble liquid and preventing decomposition

- Improvement in user convenience through the domestically patented lower drainage structure

An example of lower drainage

Simple detachment & attachment of sludge bucket

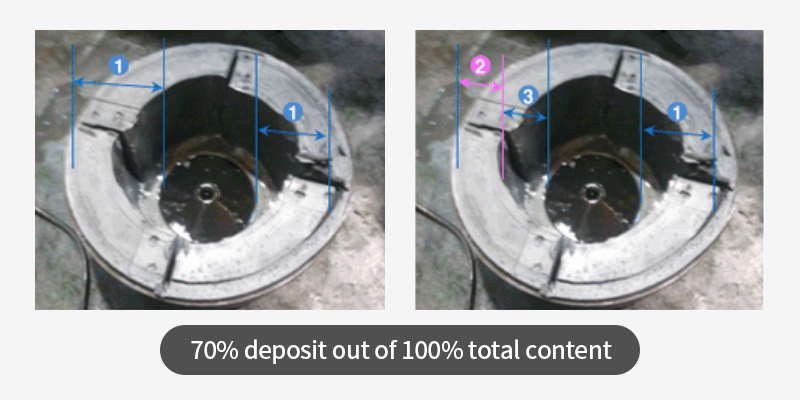

- Prevention of uneven sludge deposition through the domestically patented minimum vortex-vibration structure

An example of the prevention of uneven sludge deposition

An example of centerless grinder application

Applied Areas

- A variety of machine tools that need the cleaning of process solution and the separation of cutting chips

- Honing, Gun Drill, Super Finishing, Ultrasonic Waves, Electrical Discharge Processing, Electro-polishing, Precision Grinding, Gear Grinding, Header, Washer

- A variety of processing machines that need the separation of fine particles

- Ingot/Wafer silicone, Liquid crystal, Lens, Prism, Glass processing & cutting, Whetstone, Carbon, Aluminum, Stainless powder separation

- Solution reuse through the filtration and cleaning of a variety types of lubricating and operating oil

- Cutting oil, Drawing solution, Lubricating oil, Operating oil, Cutting oil, Heat treatment solution, Grinding solution, Washing water, Zinc, Steel, Phosphate treatment water, Barrel abrasive, Washing and Car washing, Waste water of food products, Biological waste water treatment sludge

- Primary drainage treatment system necessary to dissolve solids, such as painting booth, mud, sand, and deposit

- Solid-liquid separation machines for treating waste water of livestock, etc.

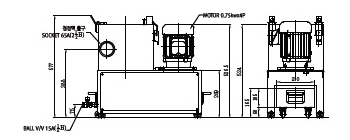

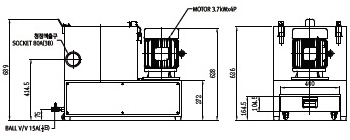

SCM-H50

-

Model Max. flow(ℓ/min) Internal capacity of rotor(ℓ) Filtration performance(㎛) Rotation count(RPM) Driving motor(kW) Installation area(W*D*H) Weight(kg) 50Hz 60Hz SCM-H50 50 4 10 2,500 3,000 0.75 355*620*590 60

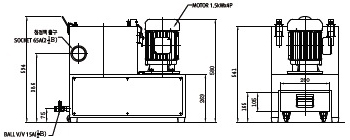

SCM-H80

-

Model Max. flow(ℓ/min) Internal capacity of rotor(ℓ) Filtration performance(㎛) Rotation count(RPM) Driving motor(kW) Installation area(W*D*H) Weight(kg) 50Hz 60Hz SCM-H80 80 7 10 2,500 3,000 1.5 380*650*581 80

SCM-H150

-

Model Max. flow(ℓ/min) Internal capacity of rotor(ℓ) Filtration performance(㎛) Rotation count(RPM) Driving motor(kW) Installation area(W*D*H) Weight(kg) 50Hz 60Hz SCM-H150 150 10 10 2,100 2,500 3.7 500*800*676 150

Product Specification

| Model | Max. flow(ℓ/min) | Internal capacity of rotor(ℓ) | Filtration performance(㎛) | Rotation count(RPM) | Driving motor(kW) | Installation area(W*D*H) | Weight(kg) | ||

|---|---|---|---|---|---|---|---|---|---|

| 50Hz | 60Hz | ||||||||

| Manual model | SCM-H50 | 50 | 4 | 10 | 2,500 | 3,000 | 0.75 | 355*620*590 | 60 |

| SCM-H80 | 80 | 7 | 10 | 2,500 | 3,000 | 1.5 | 380*650*581 | 80 | |

| SCM-H150 | 150 | 10 | 10 | 2,100 | 2,500 | 3.7 | 500*800*676 | 150 | |

※ The above specifications are changeable for product performance improvement. Filtration performance is based on experimental values, and is changeable depending on solution viscosity and specific gravity of particulate matter.

CE

Installation cases of manual model

Samsung (Vietnam factory) semiconductor processing

Samsung (Vietnam factory) semiconductor processing

Brass processing

Ceramic processing

Grinder processing

Grinding process for automotive gear

Quartz processing

Resin and glass fiber dust

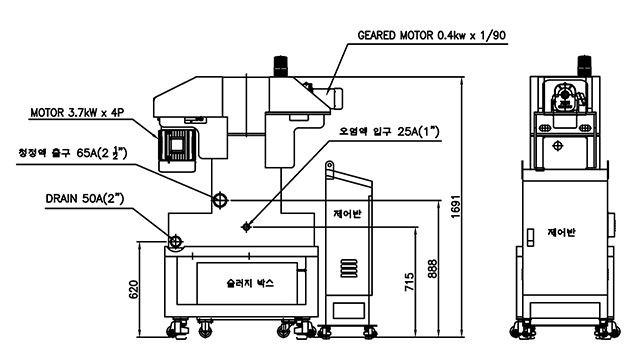

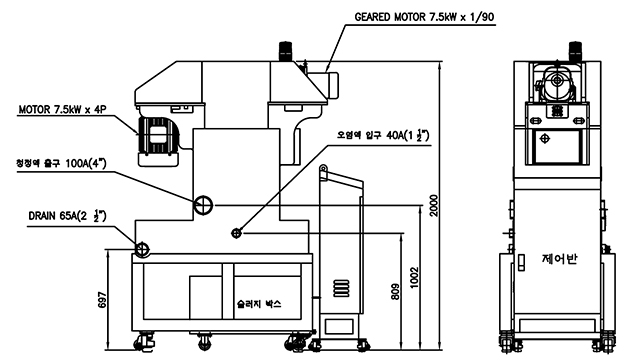

SCA-R70

-

Model Max. flow(ℓ/min) Internal capacity of rotor(ℓ) Filtration performance(㎛) Rotation count(RPM) Driving motor(kW) Installation area(W*D*H) Weight(kg) 50Hz 60Hz SCA-R70 70 10 10 1,800 2,200 3.7 630*1000*1830 700 SCA-R150

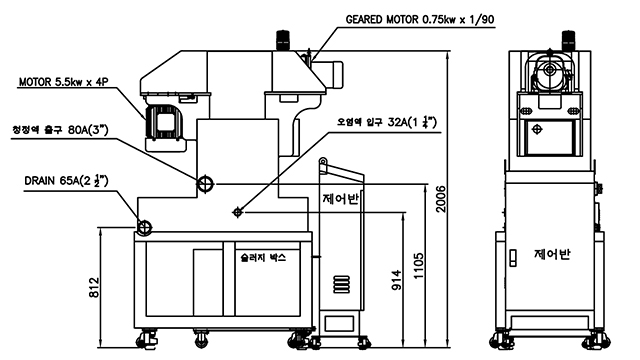

-

Model Max. flow(ℓ/min) Internal capacity of rotor(ℓ) Filtration performance(㎛) Rotation count(RPM) Driving motor(kW) Installation area(W*D*H) Weight(kg) 50Hz 60Hz SCA-R150 150 15 10 1,800 2,200 5.5 730*1200*2040 800 SCA-R300

-

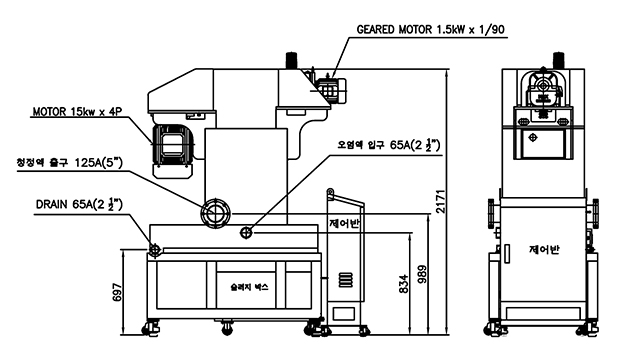

Model Max. flow(ℓ/min) Internal capacity of rotor(ℓ) Filtration performance(㎛) Rotation count(RPM) Driving motor(kW) Installation area(W*D*H) Weight(kg) 50Hz 60Hz SCA-R300 300 25 10 1,800 2,200 7.5 800*1250*2140 1,000 SCA-R500

-

Model Max. flow(ℓ/min) Internal capacity of rotor(ℓ) Filtration performance(㎛) Rotation count(RPM) Driving motor(kW) Installation area(W*D*H) Weight(kg) 50Hz 60Hz SCA-R500 500 40 10 1,800 2,200 15 885*1420*2300 1,200

Product Specification

Model Max. flow(ℓ/min) Internal capacity of rotor(ℓ) Filtration performance(㎛) Rotation count(RPM) Driving motor(kW) Installation area(W*D*H) Weight(kg) 50Hz 60Hz Automatic model SCA-R70 70 10 10 1,800 2,200 3.7 630*100*1830 700 SCA-R150 150 15 10 1,800 2,200 5.5 730*1200*2040 800 SCA-R300 300 25 10 1,800 2,200 7.5 800*1250*2140 1,000 SCA-R500 500 40 10 1,800 2,200 15 885*1420*2300 1,200 ※ The above specifications are changeable for product performance improvement. Filtration performance is based on experimental values, and is changeable depending on solution viscosity and specific gravity of particulate matter.

Installation cases of automatic model

MCT & Grinder processing

Optical lens processing

Marine deposit

Silicone processing

Glass product processing

Glass product processing(Chinese company)

Ceramic processing tank system

Ceramic processing tank system

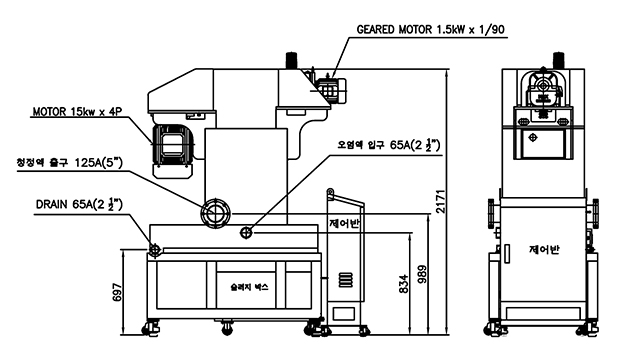

SCA-R500

-

Model Max. flow(ℓ/min) Internal capacity of rotor(ℓ) Filtration performance(㎛) Rotation count(RPM) Driving motor(kW) Installation area(W*D*H) Weight(kg) 50Hz 60Hz SCA-R500 500 40 9 1,800 2,200 11 1,004*1,740*2,400 1000

Product Specification

Model Max. flow(ℓ/min) Internal capacity of rotor(ℓ) Filtration performance(㎛) Rotation count(RPM) Driving motor(kW) Installation area(W*D*H) Weight(kg) 50Hz 60Hz Solid-liquid model SCA-R500 500 40 9 1,800 2,200 11 1,004*1,740*2,400 1000 ※ The above specifications are changeable for product performance improvement. Filtration performance is based on experimental values, and is changeable depending on solution viscosity and specific gravity of particulate matter.

Installation cases of solid-liquid model

Livestock manure

Livestock manure

Livestock manure

Livestock manure

Solid-liquid model

- Livestock manure Processing Only

- Agricultural machinery registration book registration model, Available on government loans

- Agricultural machinery registration book product code : 2100047673385

Dual model

- 1Unmanned auto system

- 224-hour full operation system (minimum non-operating time of centrifuge and maximization of its workability)

- 3Two centrifuge units controllable through control panel

- 4Low-cost and high-efficiency system

- 5Various types of sludge separable through detailed control system

- 6Individual controllability of each centrifuge if separated

Product Specification

Model Max. flow(ℓ/min) Internal capacity of rotor(ℓ) Filtration performance(㎛) Installation area(W*D*H) Weight(kg) Dual model SCA-R70 140 10*2 10 1,340*2,600*4,800 1,400 SCA-R150 300 15*2 10 1,900*3,120*5,300 1,600 SCA-R300 600 25*2 10 2080*3,250**5,560 2,000 SCA-R500 1000 40*2 10 2,300*3,700*6,000 2,400 ※ The above specifications are changeable for product performance improvement. Filtration performance is based on experimental values, and is changeable depending on solution viscosity and specific gravity of particulate matter.

Installation cases of dual model

Semiconductor processing

Grinder processing

Glass processing

Brass copper processing

[50875] 20-20, Techno valley 1-ro, Jillye-myeon, Gimhae-si, Gyeongsangnam-do, Republic of Korea TEL. +82-55-337-2947 FAX. +82-55-322-2947 E-MAIL. now@nowens.co.kr

[50875] 20-20, Techno valley 1-ro, Jillye-myeon, Gimhae-si, Gyeongsangnam-do, Republic of Korea TEL. +82-55-337-2947 FAX. +82-55-322-2947 E-MAIL. now@nowens.co.kr